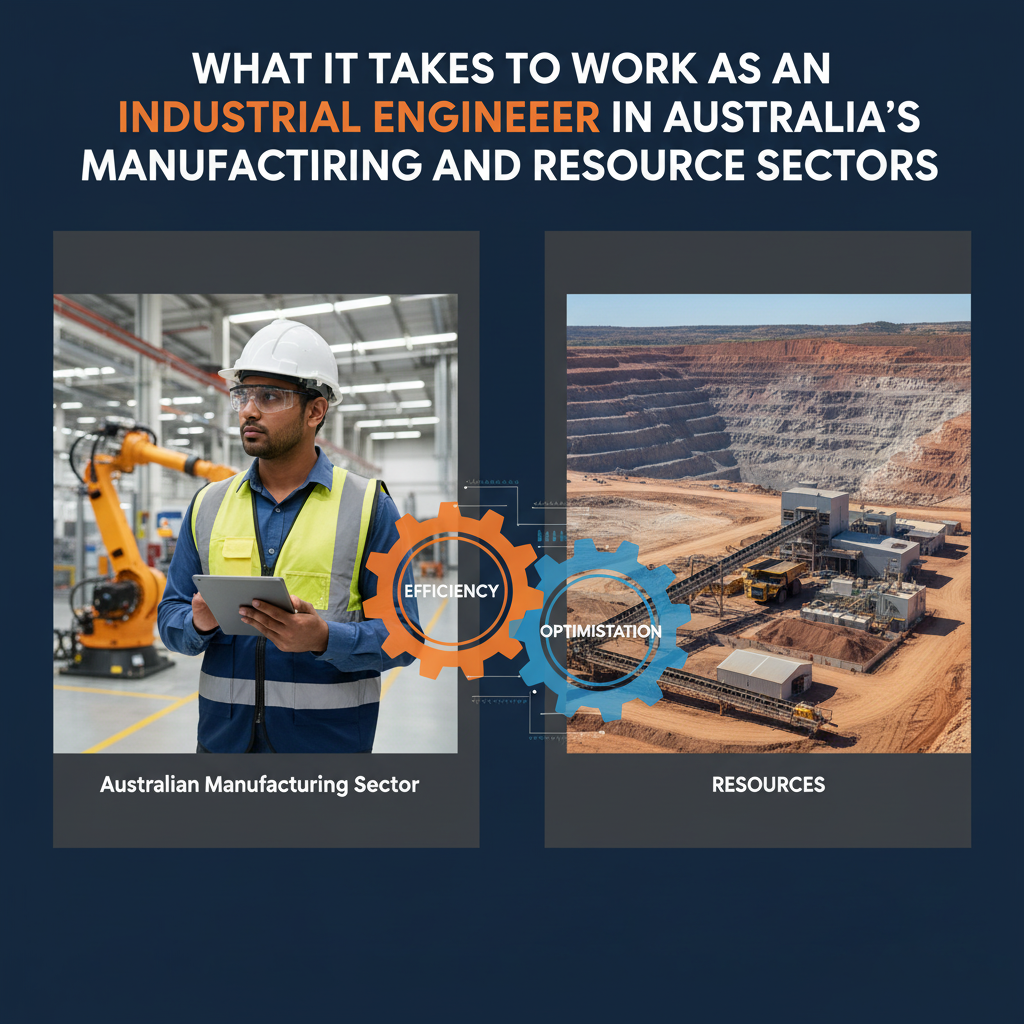

Unlock your potential as an Industrial Engineer in Australia. Learn about the essential skills (Lean, Six Sigma), migration pathways (ANZSCO 233511, Skills Assessment), and high-paying jobs in the Australian Manufacturing Sector and Australian Resource Sector.

The drive for Efficiency and Optimisation sits at the heart of Australia’s economic success. With global supply chain pressures and a relentless push for sustainability, industries across the continent demand specialists who can streamline complex operations. This crucial role is filled by the Industrial Engineer. A national Engineering Shortage Australia fuels the demand, making the career pathway for a skilled Industrial Engineer particularly bright, especially within the powerhouse Australian Manufacturing Sector and the highly lucrative Australian Resource Sector.

If you are a professional Industrial Engineer looking to migrate, understanding the specific skills, visa requirements, and sector-specific demands is your first step. This guide breaks down what it truly takes to succeed in this demanding and rewarding Industrial Engineering Jobs market.

The Core Role: Process Improvement and Waste Elimination

An Industrial Engineer’s primary function is to eliminate Waste Elimination and maximise productivity. They are not focused on a product’s design but on the process of making or delivering it. In the context of the vast Australian Manufacturing Sector—from automotive to defense—this means continuously analysing production lines to enhance output and quality. In the Australian Resource Sector, it involves optimising the movement of materials (known as Materials Handling) and improving the massive, complex logistical systems that transport minerals like iron ore or copper from mine to port.

The core of the job description (ANZSCO 233511) involves rigorous application of methodologies like Lean Manufacturing and Six Sigma. These are essential tools for a modern Industrial Engineer in Australia.

- Lean Manufacturing: Focuses on eliminating non-value-added activities, reducing delays, and improving the speed and flow of production.

- Six Sigma: Emphasises reducing variation in processes to near-perfect levels, ensuring quality and predictability.

Engineers implement Time and Motion Study techniques, create detailed Workflow Optimization models, and leverage Operations Research to make data-driven decisions. They translate complex analytical findings into practical, on-the-ground changes that boost a company’s Performance Metrics (or KPIs).

Industrial Engineering in Manufacturing vs. Resources

While the underlying principles of Process Improvement remain constant, the application of Industrial Engineering differs significantly between the Australian Manufacturing Sector and the Australian Resource Sector (including mining and minerals processing). Understanding these differences is key to targeting the right Industrial Engineering Jobs.

Australian Manufacturing Sector

In manufacturing, the industrial engineer often works directly with Production Planning and Quality Engineering. The focus is on precision, volume, and complex assembly lines. Key tasks include designing efficient factory facility layout, integrating automation, and perfecting Supply Chain synchronisation from raw material to finished goods. A professional might specialise in the Defense Industry Engineering Australia, requiring stringent compliance and documentation, or in large-scale Production Planning for the growing non-metals manufacturing industry. Stability is a hallmark of this sector, with roles often located in major metropolitan hubs like Sydney, Melbourne, and Adelaide.

Australian Resource Sector

The resource sector presents a more dynamic and, often, a higher-paying environment, though it may require a more rugged work lifestyle, such as being a FIFO Engineer (Fly-In/Fly-Out). Projects are typically larger, dealing with massive volumes of material like Iron Ore or Lithium. Here, the industrial engineer’s skills in Systems Engineering and Logistics are paramount.

The job involves:

- Materials Handling Optimisation: Ensuring the efficient flow of raw materials through crushers, processing plants, and conveyor systems.

- Plant Engineering: Working on Brownfield Projects (upgrading existing sites) or Greenfield Projects (building new facilities) to achieve maximum equipment utilisation.

- Safety and Compliance: Integrating safety protocols directly into the work processes to meet strict regulatory standards prevalent in Mining Sector operations.

Salaries in the resource sector, particularly in Western Australia and Queensland, are typically higher due to the regional location, the scale of operations, and the specialized nature of Process Improvement in harsh environments.

Your Migration Pathway: Skills, Visas, and Registration

To work as an Industrial Engineer Australia, an overseas professional must navigate a specific immigration and professional registration pathway. Success depends on achieving a positive Skill Assessment and accumulating sufficient points for a Skilled Migration Visa Australia Engineer.

- The Skills Assessment via Engineers Australia (EA)

The most crucial step is securing a positive Skill Assessment from Engineers Australia (EA), the designated assessing authority for the ANZSCO 233511 code. You must demonstrate that your qualifications and experience meet Australian professional standards. The primary pathway is the Competency Demonstration Report (CDR), which requires:

- Academic Qualification: A recognised Bachelor’s degree or higher in Industrial Engineering or a closely related field (e.g., Mechanical Engineering with a specialisation).

- Career Episodes (CEs): Three reports detailing specific engineering projects where you applied your technical and soft skills, showcasing your ability to conduct Process Improvement, Workflow Optimization, and use complex methodologies.

- Continuing Professional Development (CPD): A list showing how you stay current with industry trends (e.g., certifications in Lean Manufacturing or Six Sigma).

- The Skilled Migration Visa

A positive skills assessment allows you to submit an Expression of Interest (EOI) via the SkillSelect system for points-tested visas like the Skilled Independent (subclass 189) or Skilled Nominated (subclass 190).

| Key Visa Requirement | Details |

|---|---|

| Points Test Score | Minimum 65 points is required, but current Engineering Shortage Australia demand means competitive scores are often higher (85-100+). Points are awarded for age, English level, work experience, and qualifications. |

| English Language | Minimum ‘Competent English’ (e.g., IELTS 6.0 in each band), but aiming for ‘Proficient’ (IELTS 7.0) or ‘Superior’ (IELTS 8.0) adds significant points. |

| State Nomination (190) | A nomination from a state or territory (e.g., NSW, VIC, WA) adds 5 points and can offer a more achievable pathway. |

- Salary and Career Outlook

The Engineering Salary Australia for Industrial Engineers is highly competitive. While salaries in the Australian Manufacturing Sector are strong, the Australian Resource Sector often commands a premium.

| Sector | Average Industrial Engineer Salary (AUD) | Lifestyle Factor |

|---|---|---|

| Manufacturing | $80,000 – $110,000+ | Stable, city-based work, traditional hours. |

| Resources | $100,000 – $150,000+ (often higher for FIFO/Senior roles) | Regional, project-based, potential FIFO Engineer rosters. |

Mid-career industrial engineers with expertise in Six Sigma and Operations Research can easily transition into management and consulting roles, significantly boosting their earning potential.

Practical Steps for Success in the Australian Job Market

Landing an Industrial Engineering Jobs role in Australia requires more than just a visa. It demands cultural acclimatisation and an understanding of local business priorities.

- Localise Your Keywords: Ensure your CV and interview pitch focus on the results you achieved using Australian-relevant methodologies. Highlight your experience in Process Improvement, Logistics, Waste Elimination, and your familiarity with quality standards used in the Australian Manufacturing Sector.

- Network within Industry Bodies: Engage with Engineers Australia (EA) beyond the skills assessment. Attend their events to network with local professionals and gain insights into regional job demands, especially the need for Grad Program Engineer Australia entrants or experienced managers.

- Understand the Regional Need: Research the major resource hubs like Perth (for Iron Ore) and Brisbane (for various minerals and energy) if you are targeting the resource sector. If manufacturing is your focus, look at roles in the defense and food processing hubs in the eastern states. The job is often about solving a shortage, so demonstrating specific industry knowledge is a distinct advantage.

Your Future as an Industrial Engineer Australia

Australia presents a vast opportunity for skilled Industrial Engineers. The nation’s commitment to global competitiveness in the Australian Manufacturing Sector and the scale of the Australian Resource Sector guarantee a sustained demand for professionals who can drive Efficiency and Optimisation. Your specialised skills in Process Improvement and Systems Engineering are the solution to an endemic Engineering Shortage Australia. Navigate the ANZSCO 233511 pathway successfully, focus on localising your expertise, and prepare for a rewarding and high-impact career Down Under.

Actionable Insight: Begin your journey today by compiling your three engineering projects into Engineers Australia-ready Career Episodes to secure your positive Skill Assessment.